Infrared Thermography for Electrical Applications

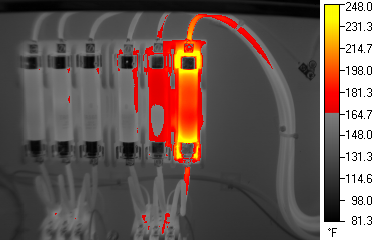

Using infrared, you would be able to 'see' areas of increased resistance indicating degradation

Using infrared, you would be able to 'see' areas of increased resistance indicating degradation

If you try to imagine life without electricity, you will quickly realize that virtually every building, facility or process in the industrial world requires electrical energy to operate.

Since it is imperative to have electricity available at all times, electrical systems must be inspected on a regular basis for potential problems that could lead to failure.

Deterioration is usually accompanied by an increase in resistance. This increase in resistance appears as heat, which can be “seen” by an infrared camera. In fact, high electrical resistance is the most common cause of thermal hot spots in electrical systems. As the resistance to the flow of current continues to increase, the temperature will continue to rise until a failure occurs. This is always costly and quite often dangerous.

Infrared helps you identify problems before failure occurs

Infrared thermography can play a vital role in identifying a wide range of problems relating to your electrical system including:

- poor connections

- overloaded circuits

- load imbalances

- faulty, mismatched or improperly installed components

- and more …

When built into a solid predictive/ preventative electrical maintenance program, infrared inspections have uncovered a multitude of potentially dangerous situations and have proven to be beneficial in reducing the number of costly and catastrophic equipment failures and unscheduled plant shutdowns.

Infrared lets you 'see' problems before they cause costly and possibly catastrophic failures

Infrared lets you 'see' problems before they cause costly and possibly catastrophic failures

Digital image of problem shown on left

Digital image of problem shown on left

Taking a systematic approach to electrical inspections

At Infrared Predictive Surveys, Inc. we take a systematic approach to your electrical inspection needs. Whether you want a quick survey of specific components or want to incorporate a full inspection as part of your low voltage or high voltage predictive/preventative maintenance program, we have certified technicians ready to serve you.

We utilize fully-radiometric infrared cameras and gather inspection data in the field using Pocket PC’s equipped with Infrared PdM inspection management software. This allows us to provide customized reports to our commercial/industrial customers and our electric utility customers showing new and recurring problems as well as trends over time toward equipment failure. Our comprehensive reports also include a prioritized list of problems and a complete inventory indicating what equipment was or was not tested.

Use the left/right slider to view the optical vs. the scanned image