Mechanical Services

Infrared Thermography for Mechanical Applications

Infrared is a useful tool for identifying

Infrared is a useful tool for identifying

potential problems in mechanical systems

Even under normal operating conditions, all machinery generates heat. However, excessive heat can be generated from friction caused by inadequate lubrication, misuse, and normal wear.

Because temperature is one of the first observable parameters to indicate the health of a component, Infrared Thermography is an excellent choice for monitoring the condition of yo

How is Infrared used in determining the health of mechanical equipment?

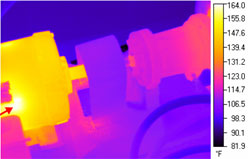

Infrared Thermography can be used to identify the amount of thermal energy (heat) being generated by a component when operating under normal load. A thermal image is captured showing the temperature distribution under normal conditions.

Once a normal thermal signature (baseline) is obtained and understood, any deviation from the normal thermal signature will then provide evidence that a potential problem is developing.

This highly-effective, non-contact, non-destructive testing method, can be used to monitor the condition of:

- bearings

- gears

- shafts

- couplings

- pulleys

- conveyers

- vacuum pumps

- clutches

- and more …