Steam System Services

Infrared Thermography for Steam Systems

Using infrared, you would be able to 'see' problem areas in steam systems

Using infrared, you would be able to 'see' problem areas in steam systems

Steam systems provides process heating, pressure control, mechanical drive, and component separation, in industrial facilities. They also provide a source of water for many process reactions.

Significant economic losses can result when steam is lost from the system through leaks. These leaks are usually caused by piping failures and steam trap failures.

Identifying pipe failures

Steam piping components can fail because of improper design, corrosion, external factors, and many other reasons. From an energy standpoint, pipe failures must be eliminated because they are a direct waste of the fuel resources. Generally, safety concerns are a major driving factor in the repair of steam piping failures. However, energy loss can help justify the maintenance expense when safety is not an issue.

Identifying steam trap failures

Steam traps are vital components in steam systems. They are designed to remove condensate from the steam distribution piping and heat exchange equipment. They also remove non-condensable gases which impede heat transfer and result in corrosion. Common causes of steam trap failure include system debris, improper sizing, and improper application.

When a steam trap fails in the open position, it allows “live” steam to discharge from the system. This type of failure can have a significant economic impact by increasing the amount of energy used, which the steam trap was installed to conserve. When a steam trap fails in the closed position it allows condensate to backup into the equipment drained by the trap. If this is a process heat exchanger, the product will not receive the energy intended. Water hammer can also result, which can damage piping components.

A well-maintained steam system will typically experience a 10% trap failure in a 1-year period. This can translate into significant losses to the system. As such, a maintenance program based on finding and eliminating steam leaks is essential to the efficient operation of a steam system.

Using Infrared Thermography in Steam System Applications

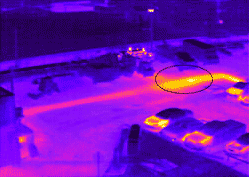

Washington Monument Steam Leak

Infrared Thermography can be used to identify thermal energy (heat) being emitted by an object allowing us to detect areas with unusual temperature patterns. When a potential problem area or component is identified, we record the image (thermal and visual) and gather details on the temperature and location of the potential fault. We will then provide this information in our report of findings so the problem can be corrected before it becomes serious.