Flat Roof Inspections

Infrared Thermography for Flat Roof Inspections

An infrared roof survey is used in a flat roof inspection to locate moisture in a roof by seeking areas of increased surface temperatures. During the cold weather season, heat from the building interior is lost at a greater rate through wet roof areas and elevates the surface temperature. Alternatively, during the warm seasons, solar heat is absorbed into the wet area, and then retained for hours after the sun sets.

To understand the methodology for infrared roof evaluations, it is important to first comprehend how thermal differences are detected and analyzed when applied to areas of wet and dry insulation. Roof areas that contain moisture have higher thermal conductivity and capacitance than dry areas. During the day, the sun radiates energy onto the entire roof surface (solar loading). Later in the day, the wet insulation has the capability to retain more energy (heat capacity). Areas of the roof that are of higher mass (wet) retain heat longer than the lower mass (dry) areas and therefore radiate heat for a longer period of time, because it takes longer to cool.

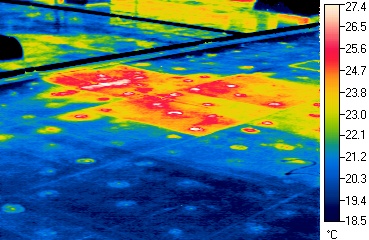

Wet areas are not always well-defined, and as this image shows, can be amorphous and need to be thoroughly investigated. This wet area is on an aluminized roof and this image was captured with a mid-wave camera.

Wet areas are not always well-defined, and as this image shows, can be amorphous and need to be thoroughly investigated. This wet area is on an aluminized roof and this image was captured with a mid-wave camera.

When viewed through the infrared imager, wet areas appear as brighter, lighter tones of gray in black and white images. Alternatively, in color images, wet areas will appear as hotter colors. In general, the higher the concentration of water, the higher the surface temperatures.

Because higher surface temperatures and consequently hotter colors may be produced by several phenomena not related to moisture intrusion, additional capacitance tests are made to verify the findings of the infrared inspection including core cuts and other non-destructive testing.

Nuclear Backscatter

Nuclear Backscatter Methodology for flat roof inspections is a non-destructive testing technique that uses a radioactive isotope consisting of Americium-241 with a beryllium target to emit high-speed neutrons aimed at the roof. The measurement method relies on the thermalization (slowing) of fast neutrons by the hydrogen atoms in water. Because water contains hydrogen, reflected neutrons indicate the presence of water in the roofing material.

Nuclear Gauge

Nuclear Gauge

The meter used, Troxler 3216, is a portable instrument with a periodic counter to measure the rate of thermalization of the neutrons.

Since other hydrogen bearing materials also thermalize neutrons, a measurement survey is necessary to establish a relative base level before an analysis can be performed. A measured roof drawing is rendered and a 5’ by 5’ or 10’ by 10’ grid pattern is established on the roof.

A number of readings are then performed to establish a relative base level before the actual analysis is performed. Testing intervals are typically 7.5 seconds at each grid point location.

Higher levels of slowed neutrons are recorded at wet areas because water contains a significant amount of hydrogen atoms. Although the meter cannot determine the quantity of moisture present in materials, it can easily determine the difference between wet and dry insulation.

This type of testing is often used to augment an infrared inspection because of its ability to “read” down approximately 8 inches and report the relative number of hydrogen atoms. If water were able to get into the top roof and travel below the insulation, it would be invisible to the infrared camera.

Capacitance / Impedance

Capacitance/impedance testing is a non-destructive testing technique used to quickly and accurately identify water entry pathways and areas of entrapped water within a roof construction. This technique is based on the ability of a material to store electrical energy.

It involves placing a moisture meter on the surface of the roof to send a safe electric current into the roof without penetrating the roof membrane. If the material is wet, the dielectric properties of the material would produce a higher meter reading than it would if the material were dry.

The Tramex Dec Scanner is a mobile device that is used for detecting relative moisture content of large roof areas. The Dec Scanner is designed for testing built up roofing and non-conductive single ply membrane. It provides instantaneous, clear indications of roof conditions and is able to detect as little as 2% excess moisture in these large-scale roofing systems.

Moisture detection readings taken with

Moisture detection readings taken with

a Tramex Dec Scanner

Moisture Verification (Core Cuts)

This core cut shows a wet sample.

This core cut shows a wet sample.

Once a complete evaluation has been performed to identify and mark all of the potential wet areas on the roof plan, it is time to determine the amount of moisture present in the marked areas. The non-destructive testing methodologies simply identify whether or not moisture is present during flat roof inspections. They do not determine the amount of moisture in the roof system.

To determine the true moisture content of a roof system, core samples need to be extracted from the affected roof areas. Core samples consist of cuts through the roof membrane down to the roof deck.

The sample provides an absolute test of moisture content and location. The core cut also permits the constituents of the roof system, and their condition, to be determined. Core samples may be weighed, dried and re-weighed to provide a quantitative measure of moisture content.

Core moisture content, measured 1" into core. The nuclear reading here is 21.

Core moisture content, measured 1" into core. The nuclear reading here is 21.